During the operation of the motor, it should maintain a stable and low-noise working state under normal circumstances. However, when there is a loud friction sound between the stator and rotor of the motor, it not only interferes with the normal working environment, but may also indicate serious faults in the motor. If not dealt with in a timely manner, it may even cause damage to the motor, resulting in economic losses and production interruptions. Exploring the reasons for the loud friction sound between the stator and rotor of a motor requires analysis from multiple aspects such as mechanical, electromagnetic, and installation.

Mechanical issues are a common factor causing loud friction sounds between the stator and rotor. The bearings of the motor, as key components supporting the rotor, can disrupt the normal operational balance of the rotor once they experience wear, poor lubrication, or damage. Bearing wear can cause the center position of the rotor to shift, resulting in uneven air gap between the rotor and stator, leading to friction. For example, motors that operate in harsh environments for a long time are prone to dust and impurities entering the interior of the bearings, accelerating their wear. In addition, the bending deformation of the motor shaft can also cause friction between the rotor and stator. The bending of the shaft may be caused by external force impact on the motor, improper operation during transportation, or long-term overload operation of the motor, resulting in uneven force on the shaft and gradual deformation, which in turn changes the relative position between the rotor and stator, causing friction and making loud noises.

Electromagnetic faults cannot be ignored either. When the motor is running, energy conversion is achieved between the stator and rotor through electromagnetic force interaction. When the three-phase power supply voltage of the motor is unbalanced, it will cause the three-phase current to be unbalanced, resulting in unbalanced magnetic pulling force. This unbalanced magnetic pulling force will cause the rotor to experience uneven electromagnetic force, resulting in displacement and friction with the stator. For example, poor contact or blown fuses in a certain phase of the power supply system can cause three-phase voltage imbalance. In addition, when faults such as inter turn short circuits or open circuits occur in the motor windings, they can also disrupt the magnetic field balance inside the motor, resulting in uneven force on the rotor and causing friction. A short circuited winding will cause an increase in current in that part, resulting in an abnormal magnetic field that breaks the originally uniform electromagnetic distribution and causes the rotor to deviate from its normal operating trajectory.

Improper installation and assembly are also important reasons for the loud friction sound between the stator and rotor. During the installation process of the motor, if the motor base is not flat and the tightening force of the installation bolts is uneven, the motor will vibrate during operation. Over time, this may cause a change in the position between the rotor and stator, leading to friction. In the assembly process of the motor, if the concentricity of the stator and rotor is not adjusted properly and the air gap is uneven, even if there are no obvious problems during the initial operation of the motor, friction will gradually increase and the sound will become louder as the operating time increases. In addition, the loosening of internal components of the motor, such as loose end cap bolts and stator core fixing bolts, can cause additional vibration during operation, increasing the risk of friction between the stator and rotor.

To solve the problem of loud friction sound between the stator and rotor of the motor, a comprehensive inspection of the motor is necessary first. Check the wear of the bearings. If severe wear is found, replace the bearings with new ones in a timely manner and choose suitable lubricating grease for lubrication to ensure the normal operation of the bearings. For motor shafts that are bent or deformed, measures such as straightening or replacement can be taken according to the degree of deformation. In terms of electromagnetics, it is necessary to check whether the three-phase power supply voltage is balanced and whether there are faults in the motor winding. If voltage imbalance or winding faults are found, relevant components should be repaired or replaced in a timely manner. Regarding installation and assembly issues, it is necessary to readjust the flatness of the motor base, tighten the installation bolts evenly, and ensure a stable installation of the motor; During assembly, strictly control the concentricity of the stator and rotor to ensure even air gap, and inspect and tighten all internal components of the motor to prevent loosening.

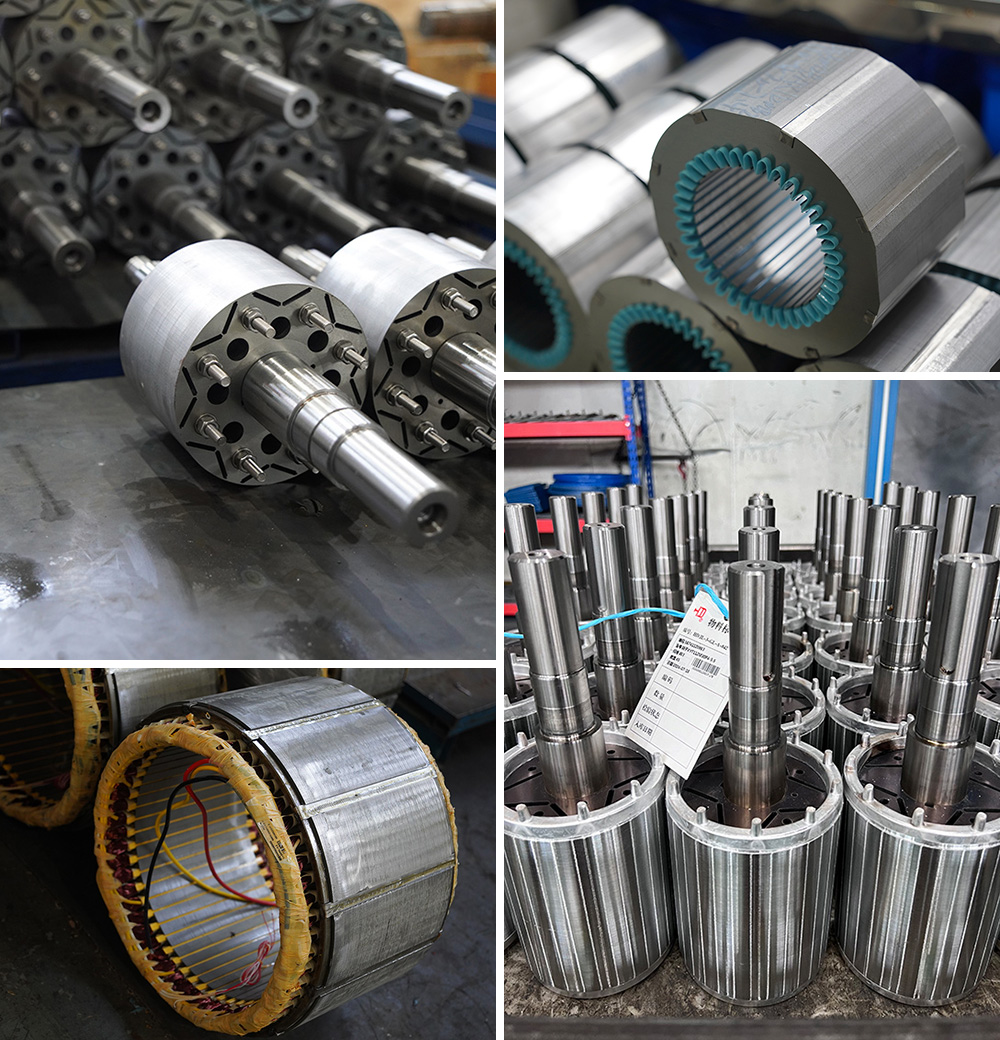

Hengda Electric has always been dedicated to the research and development, production, and service of various types of motors. With advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable motor professional solutions and creates greater social value.